Press systems for rubber products

- Compression presses

- Transfer moulding presses

- Vacuum chamber presses

- Specialty constructions for various applications

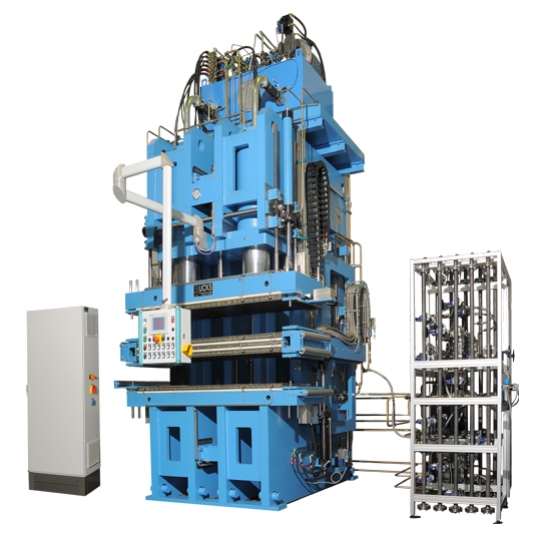

Transfer moulding press KV 268, delivered to company Gustav Möllering GmbH & Co. KG

Examples of customer-specific press systems

Vacuum chamber press KV 326

Vulcanising press KV 317

Vulcanising press KV 318

Vulcanising press KV 316

Vulcanising press KV 311

Copression press KV 327

Vulcanising press 3 x KV 309 & 1 x 310

Vulcanising press KV 307

Vulcanising press KV 266

Transfer moulding press KV 268

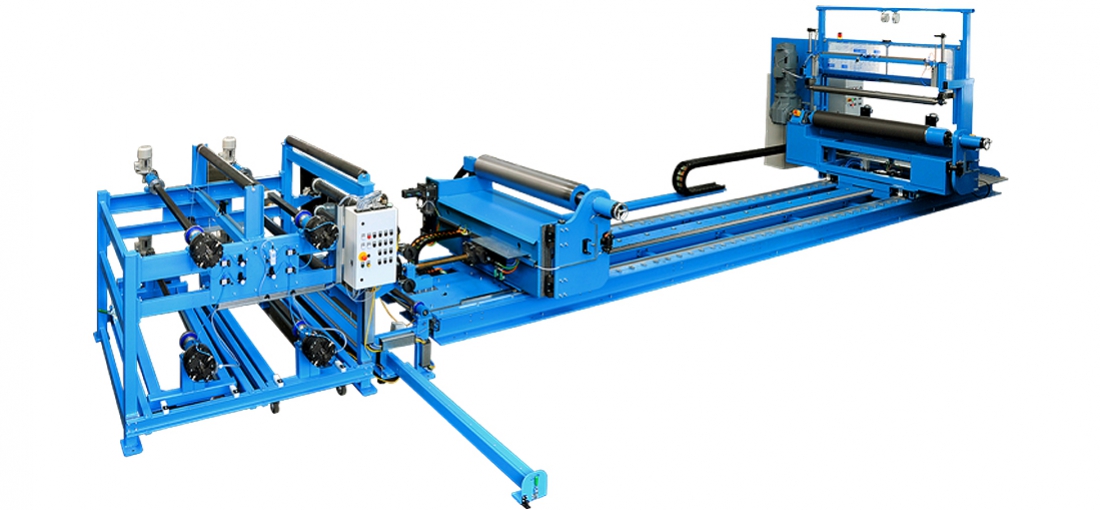

Turning and packing equipment for rubber textured belts KV 292

Transfer moulding press KV 253

Turning station

Perforation punch KV 255

Transfer moulding press KV 258

Vulcanising press KV 231

Vulcanising press KV 230

Vulcanising press KV 264

Vacuum chamber press KV 238

Vacuum chamber press KV 274

Contact partner

Mr. Andrè Göpfert

Sales

phone +49 (0) 3763 6003 - 19

fax +49 (0) 3763 6003 - 30

send email-message

Mr. Andreas Müller

Sales

phone +49 (0) 3763 6003 - 39

fax +49 (0) 3763 6003 - 30

send email-message