News

On this page, you will find current releases about our company. If you have any questions, please contact us.

With full steam in the year 2014 wishes your RUCKS team.

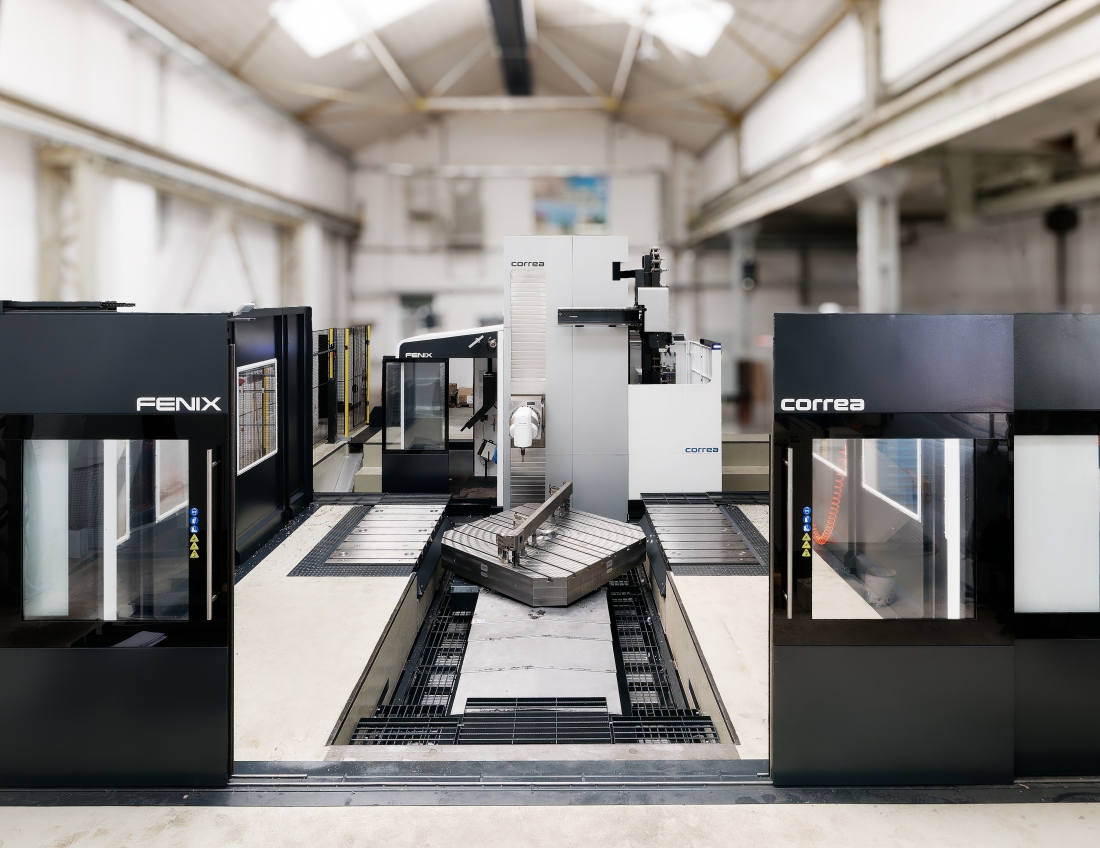

The May edition of "NC Fertigung" reported on our new milling center.

But read for yourself! Simply use the following link.

https://epaper.nc-fertigung.de/html5/Fgwtig8xHd/JhjheooZkErgo/14

Have fun reading.

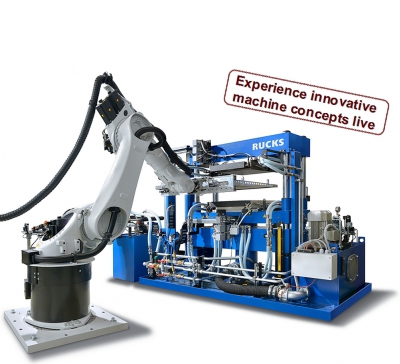

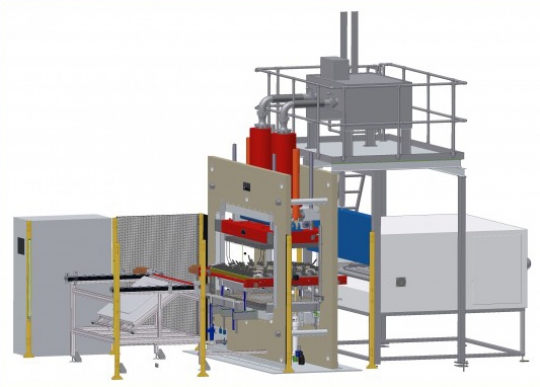

CCM System for a New Japanese Customer

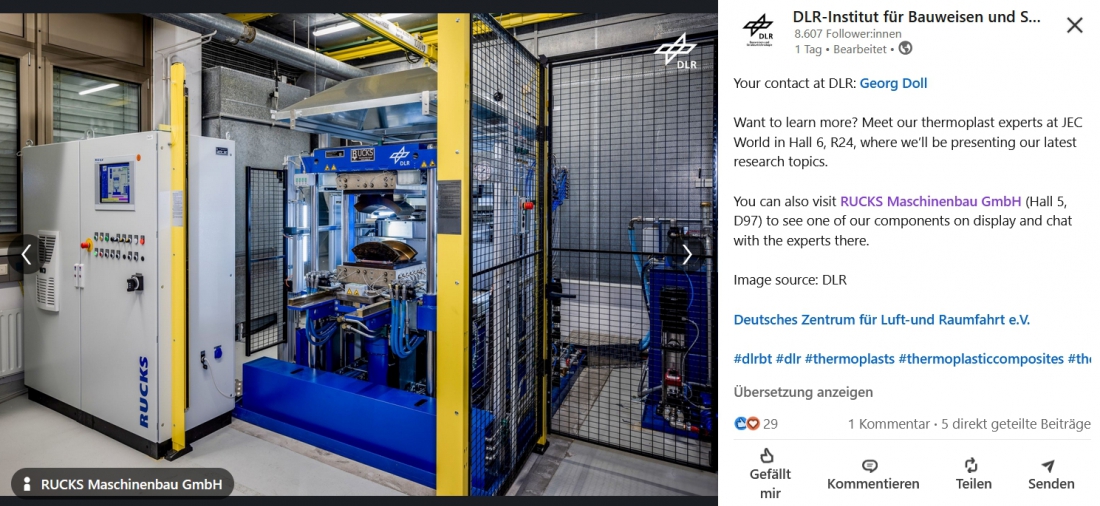

RUCKS delivers a new Continuous Compression Moulding System (CCM) to a Japanese customer

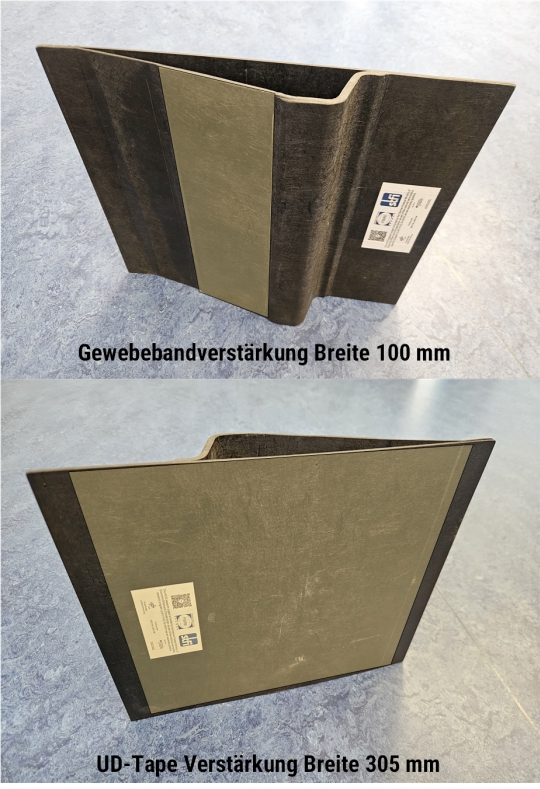

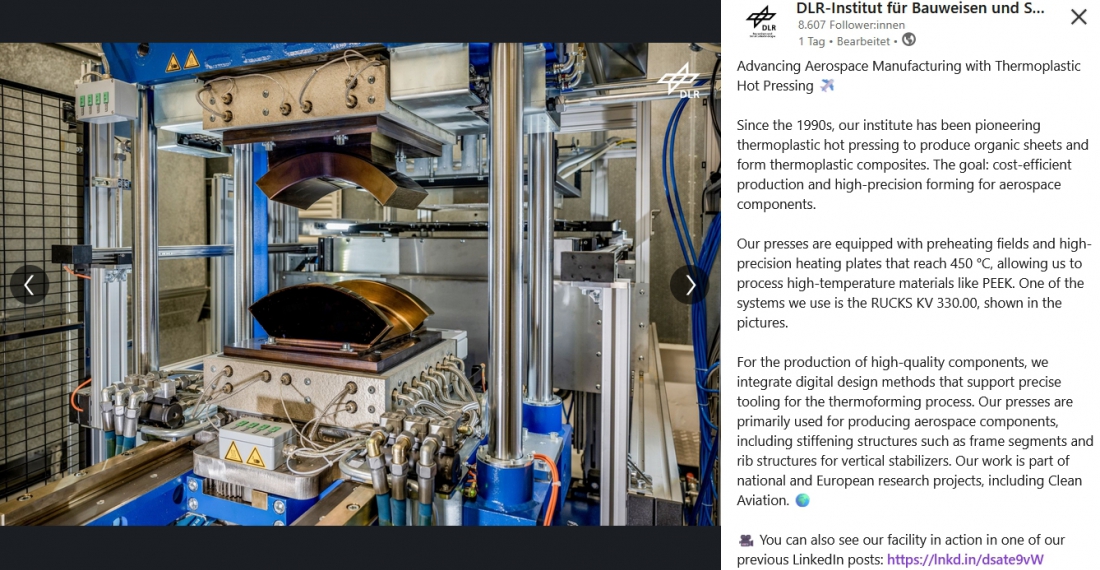

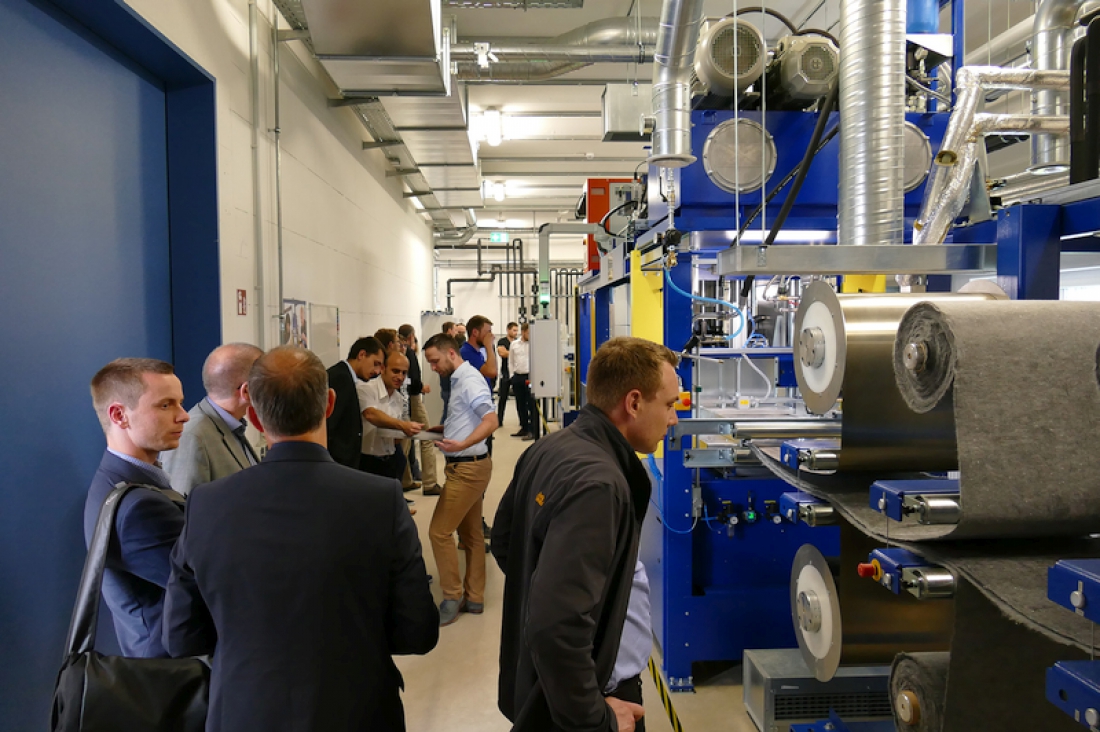

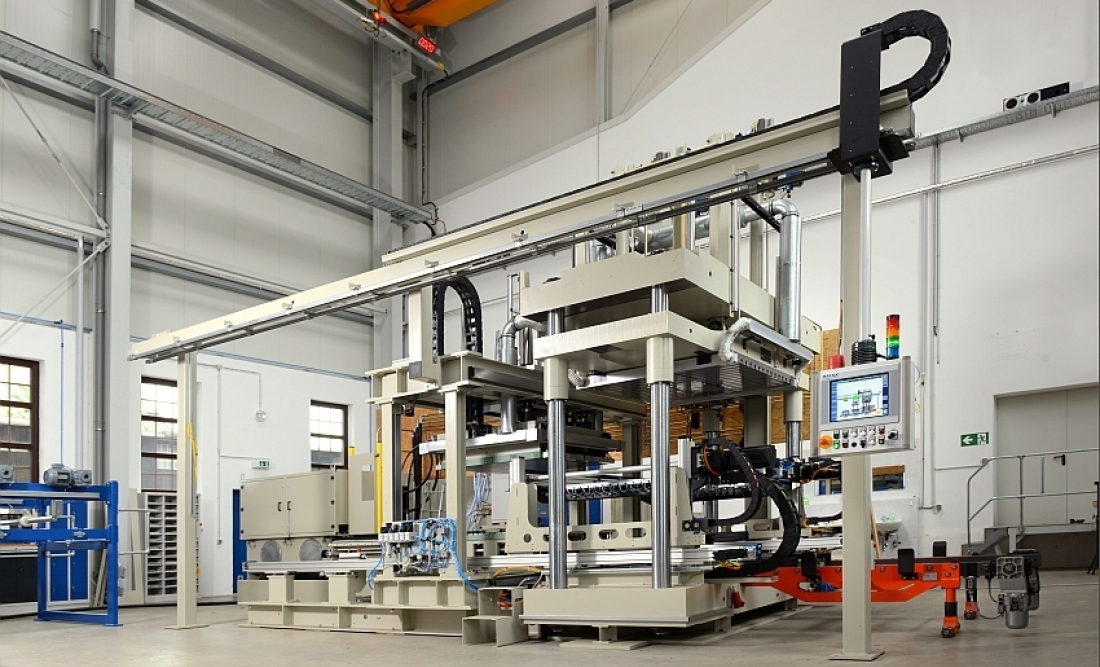

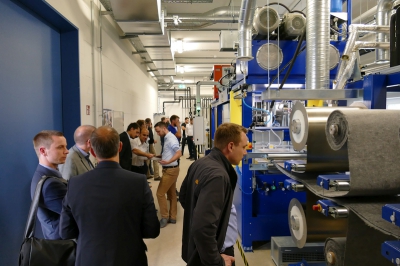

Official start up of the RUCKS – Continuous Compression Molding Press KV 325 at the STFI in Chemnitz

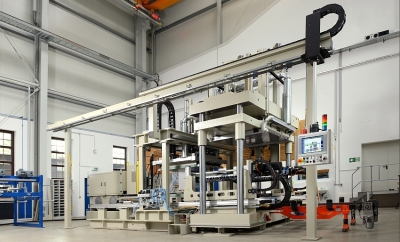

A new milling machine extends our machinery.

Contact partner

Mr. Andreas Müller

Sales

phone +49 (0) 3763 6003 - 39

fax +49 (0) 3763 6003 - 30

send email-message