Specialty Systems

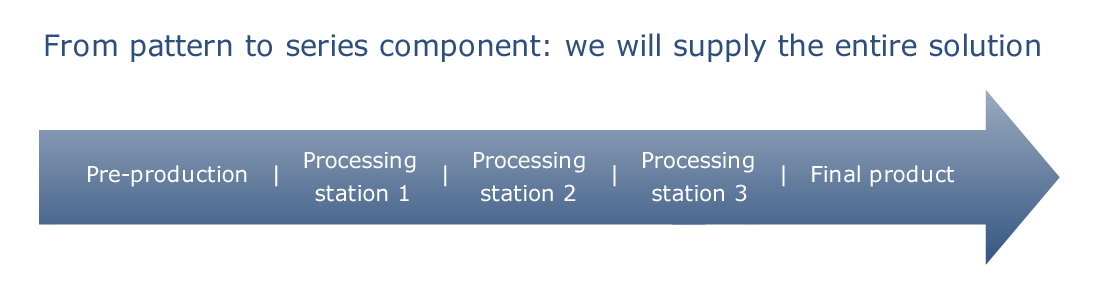

With RUCKS engineering to a specialty systems

- End product - is known

- Manufacturing process - ???

- Solution - RUCKS Engineering

Examples of customer-specific specialty systems

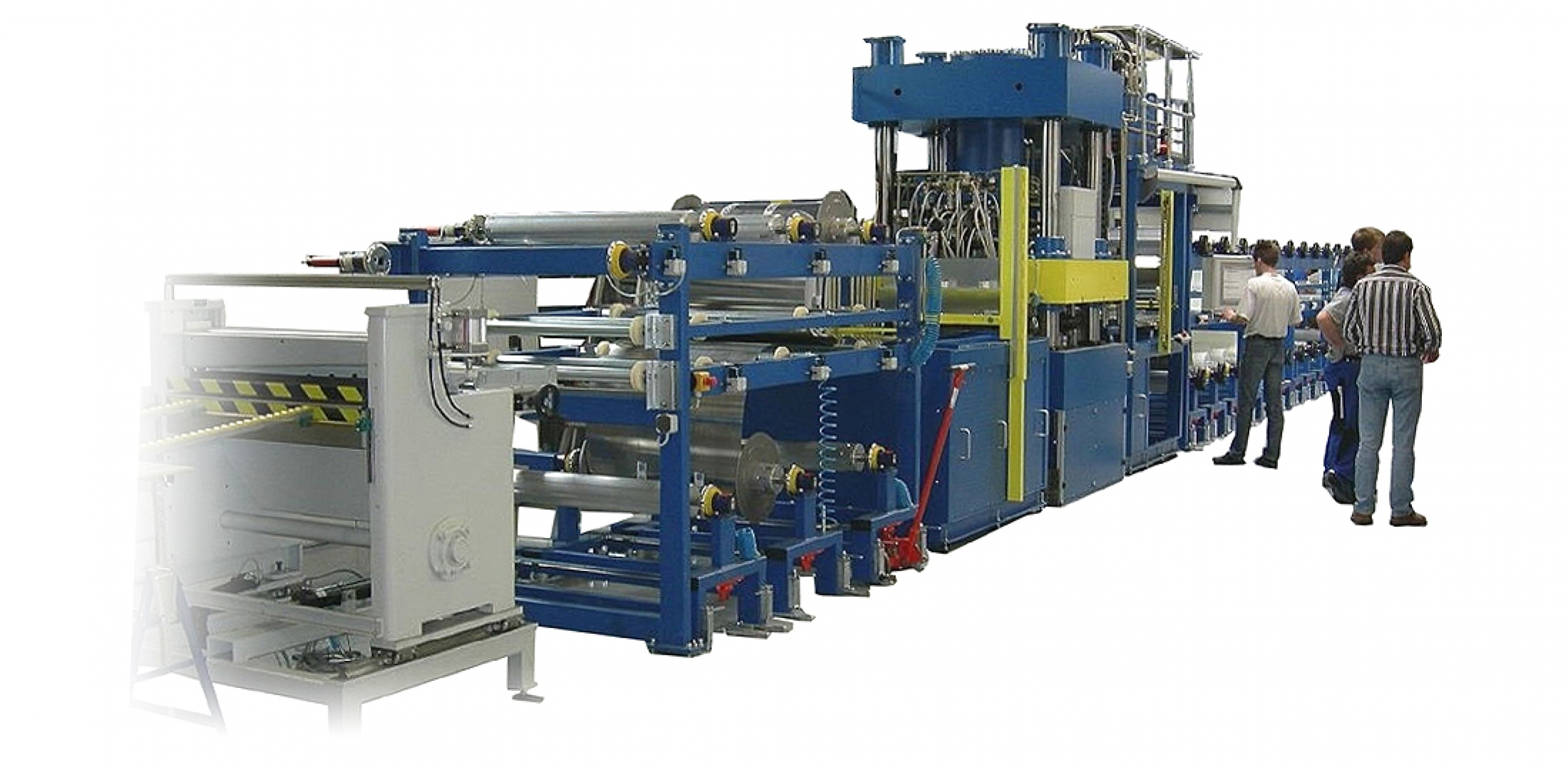

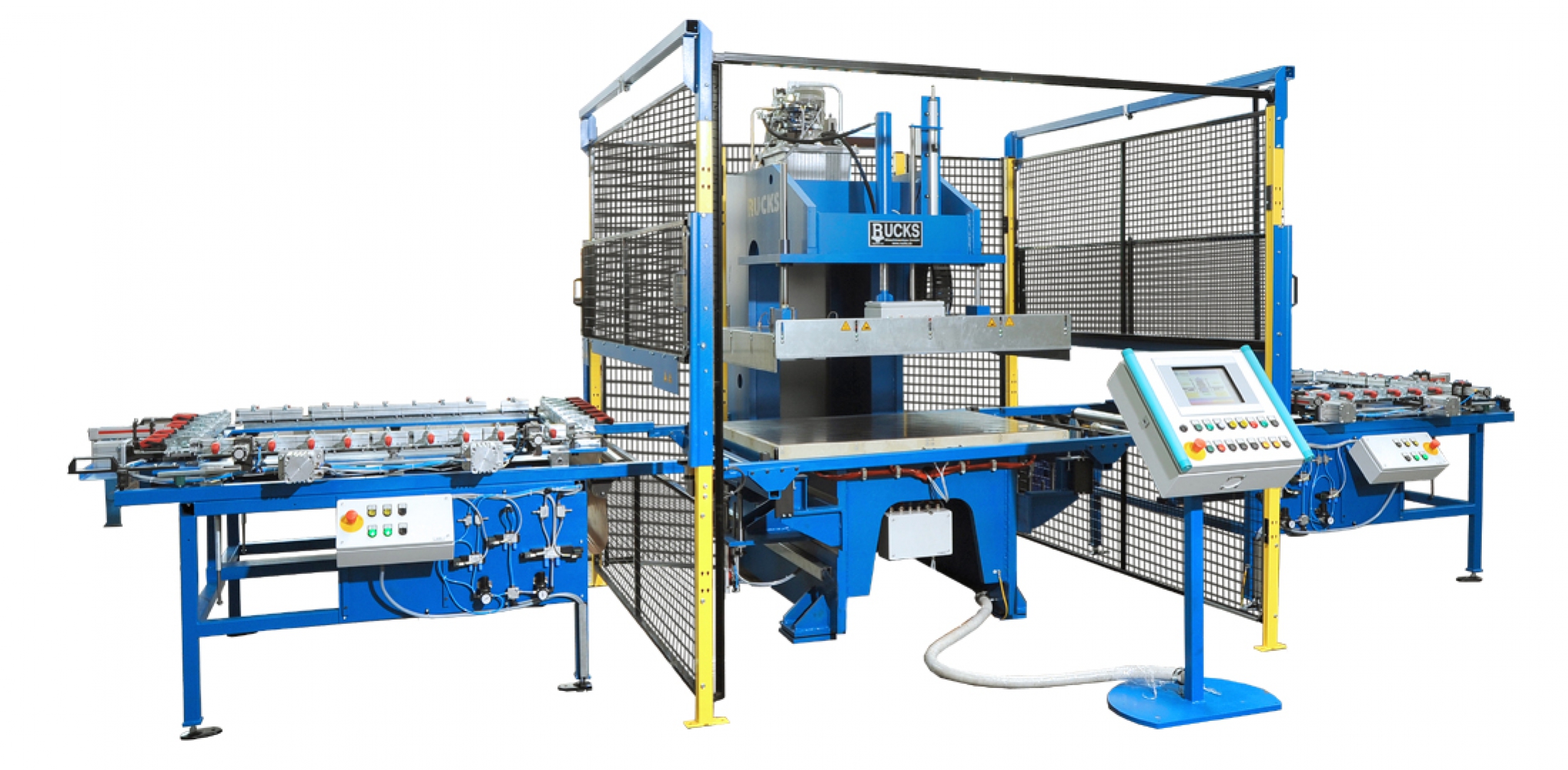

Continuous compression moulding system KV 334

Continuous compression moulding system KV 325

Fully automated thermoforming production system KV 296

Continuous compression moulding system KV 260

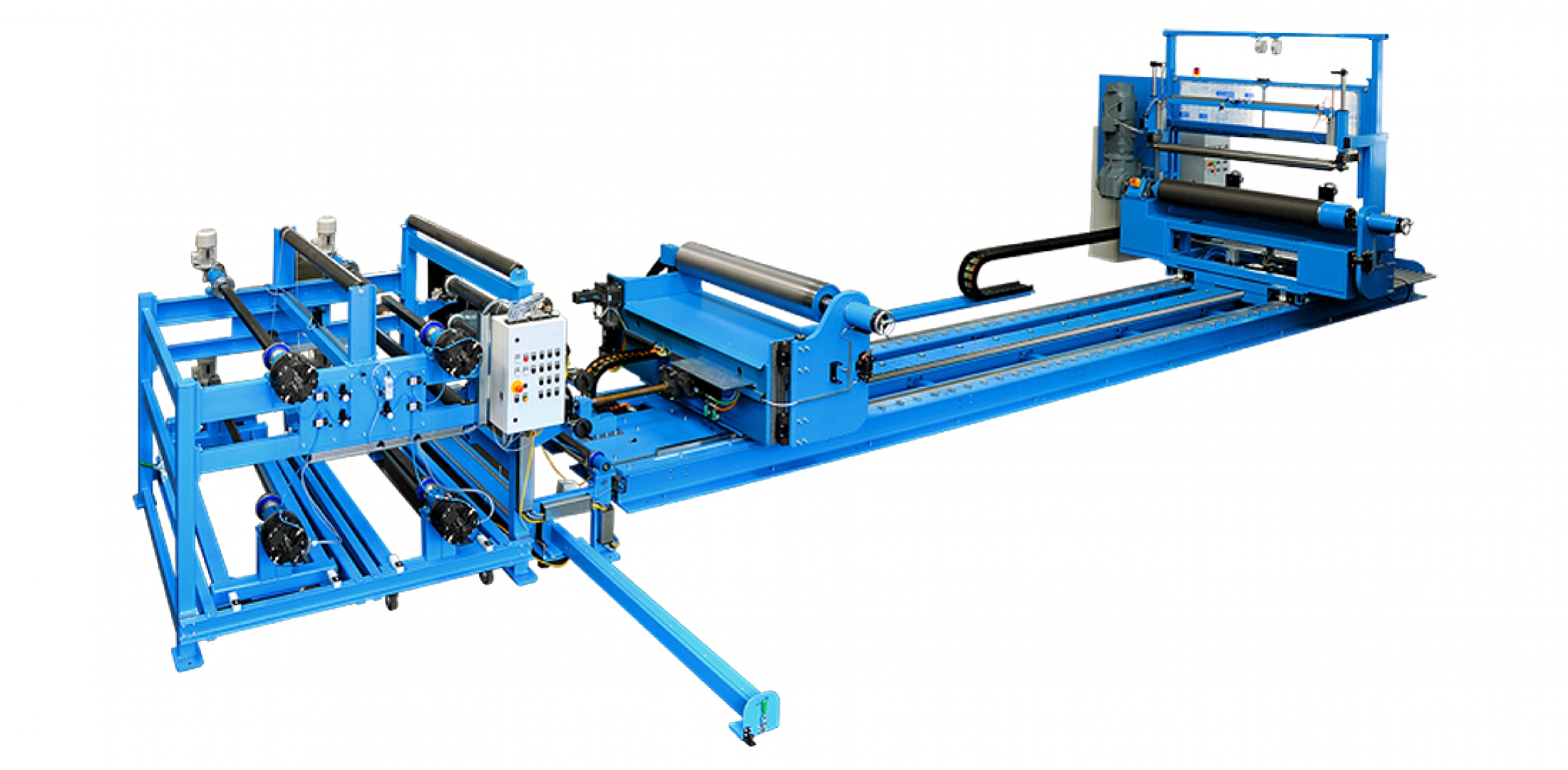

Wrapping and tailoring equipment for rubber textured belts KV 292

Turning station

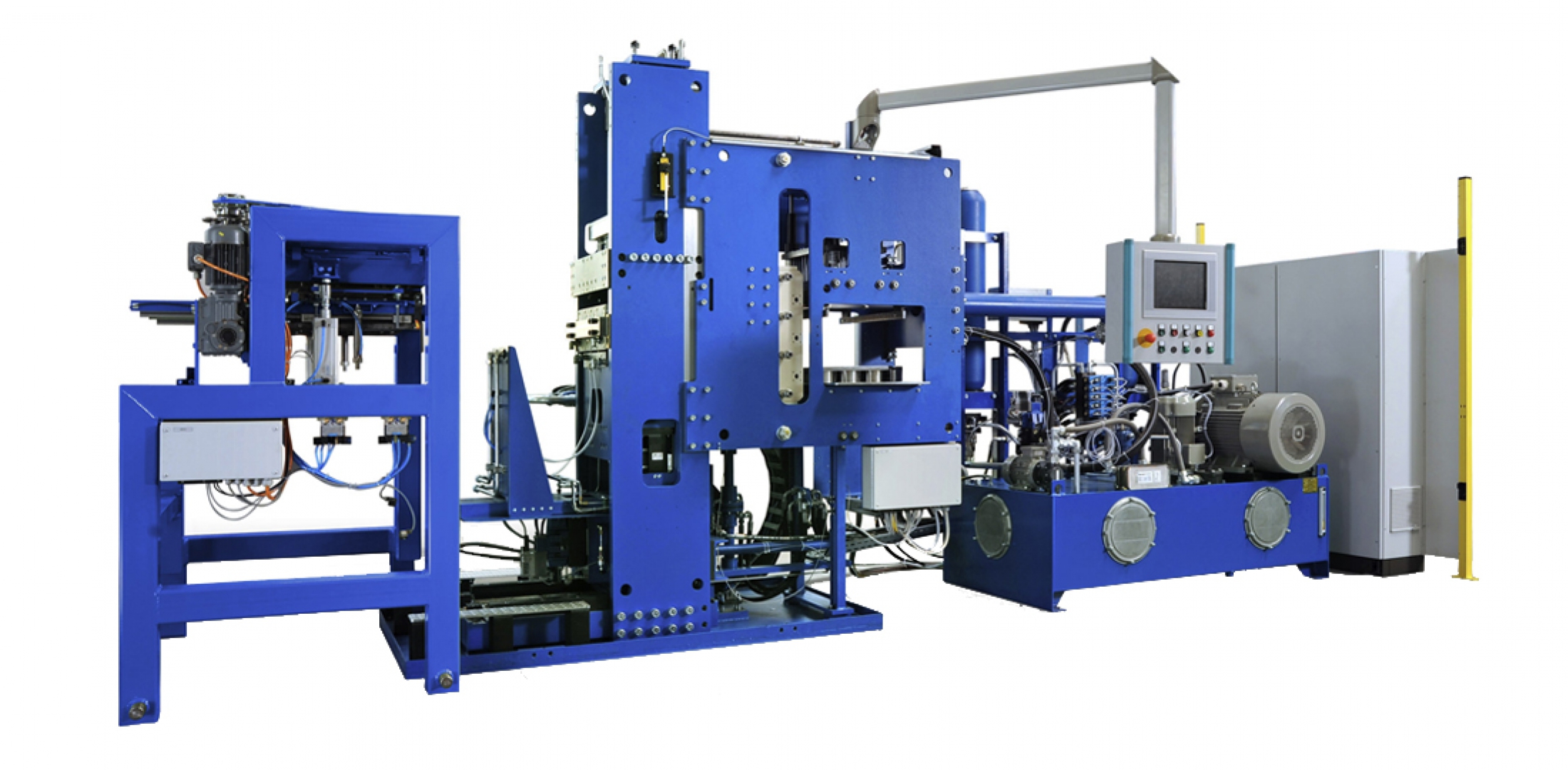

Perforation punch KV 255

Wood pile pressing system KV 291

Specialty system KV 278

Press KV 216

Press KV 285

Heating device for tubes KV 248

Contact partner

Mr. Andrè Göpfert

Sales

phone +49 (0) 3763 6003 - 19

fax +49 (0) 3763 6003 - 30

send email-message

Mr. Andreas Müller

Sales

phone +49 (0) 3763 6003 - 39

fax +49 (0) 3763 6003 - 30

send email-message