Press systems to process wooden materials

- Compression presses

- Forming presses

- Specialty constructions for various applications

Examples of customer-specific press systems

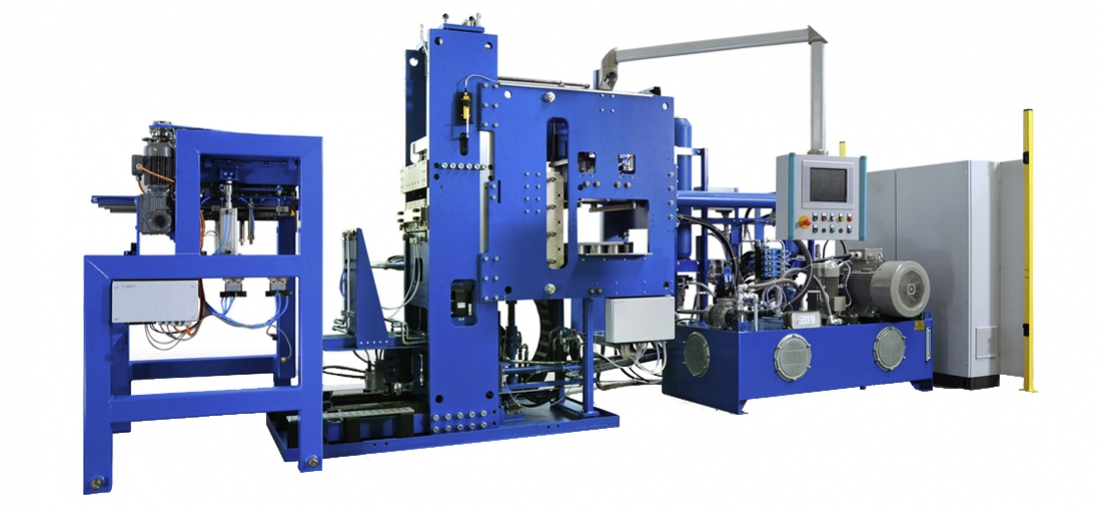

KV 321 Compression press

KV 211 Compression press

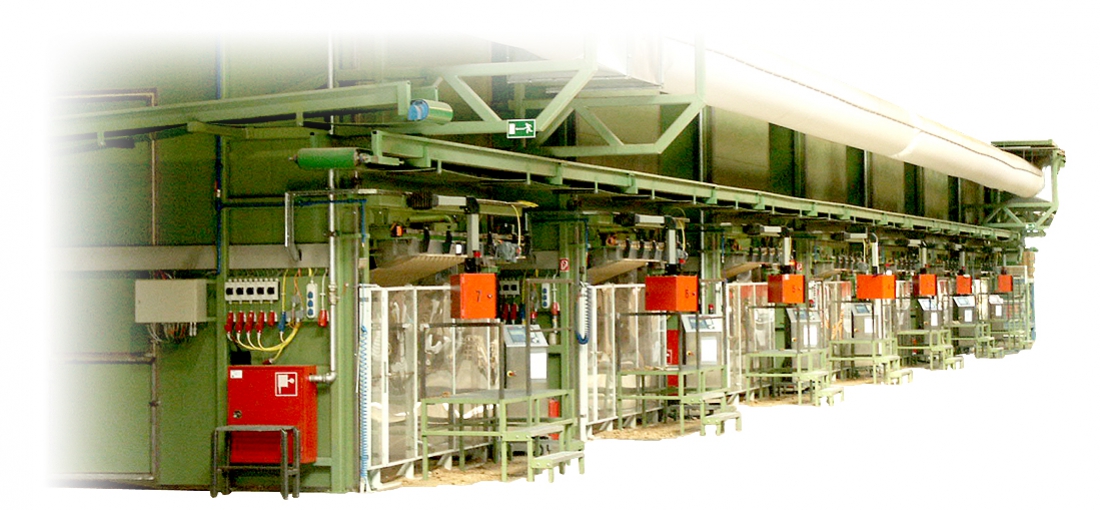

KV 291 Wood pile press system

7 presses of type KV 211

Contact partner

Mr. Andrè Göpfert

Sales

phone +49 (0) 3763 6003 - 19

fax +49 (0) 3763 6003 - 30

send email-message

Mr. Andreas Müller

Sales

phone +49 (0) 3763 6003 - 39

fax +49 (0) 3763 6003 - 30

send email-message