Engineering Projects

Your options

Use opportunities

- new innovative products using new materials

- competitive products using new concept solutions for series production systems

Develop concepts

- define requirements & objectives

Exclude risks

- Ideal overall concepts specific to the customer using RUCKS Engineering Projects

Contents

Process

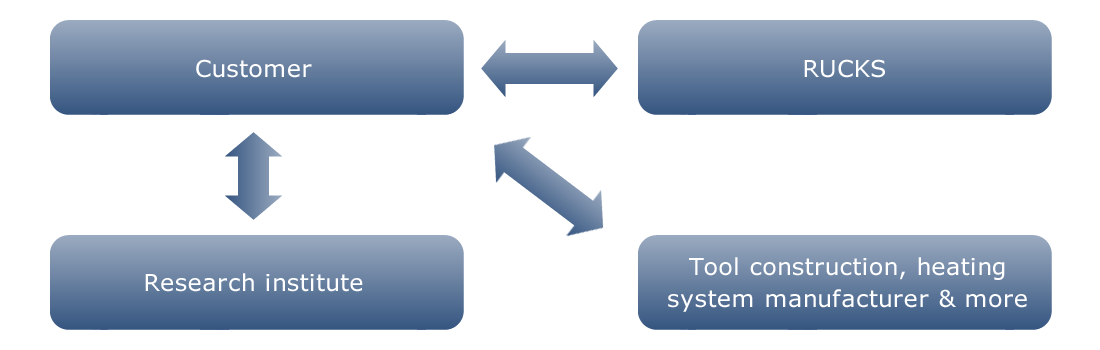

Project partners

Examples of customised integrated concepts

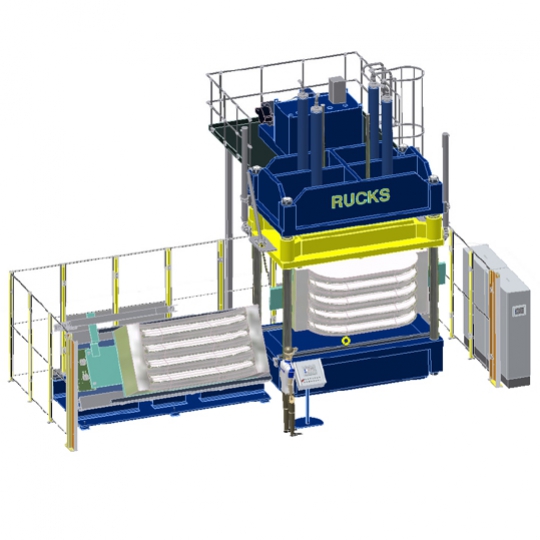

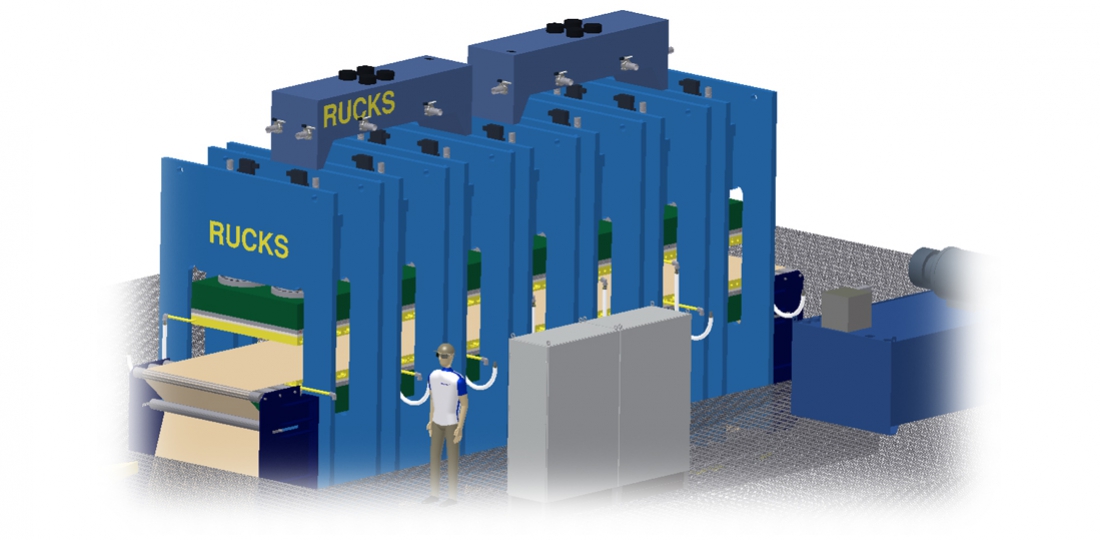

Press system for the production of drum brake coatings

Vulcanising press

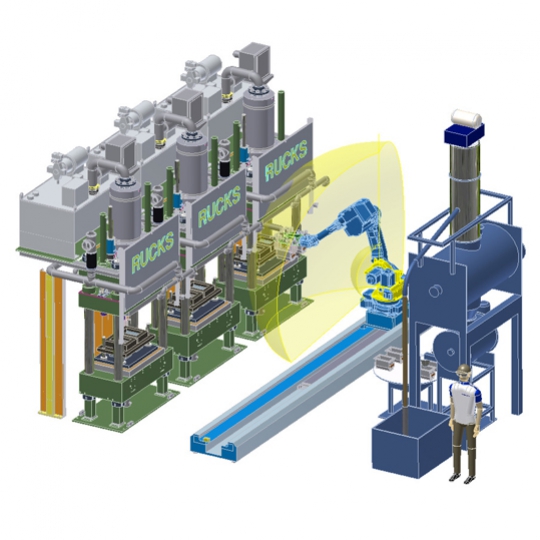

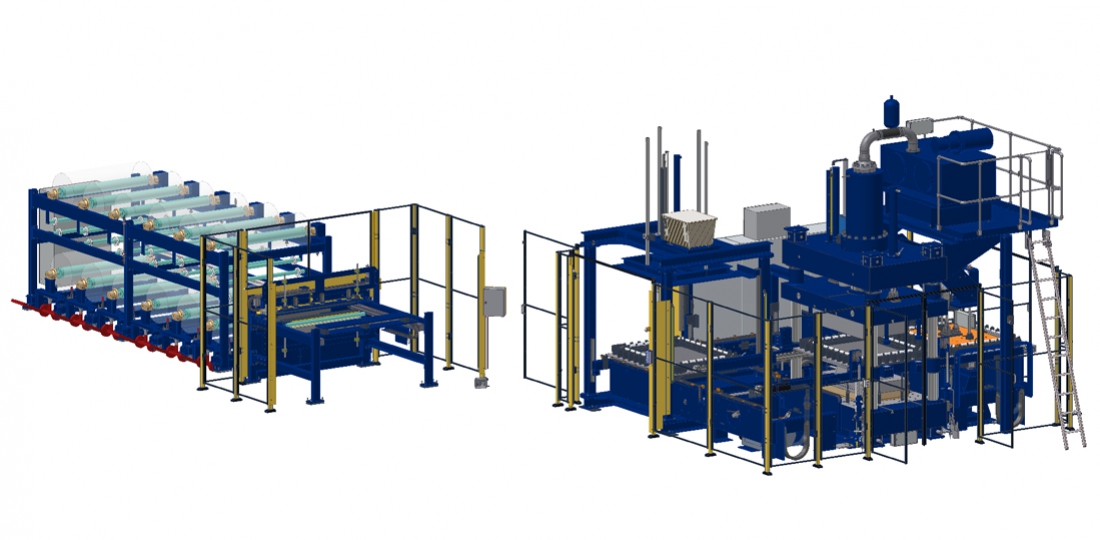

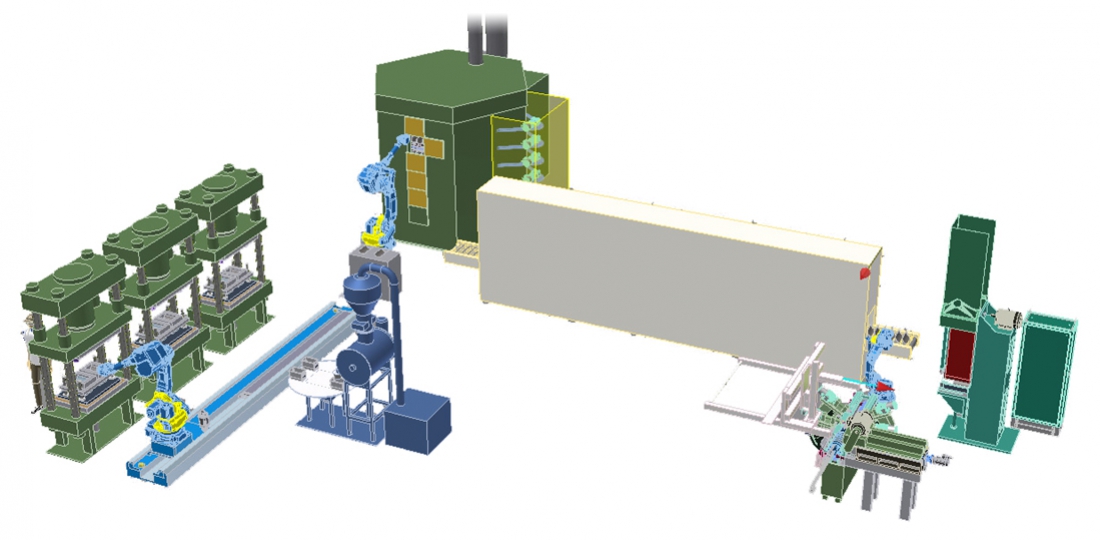

Fully automated thermoforming production system

Fully automated thermoforming production system

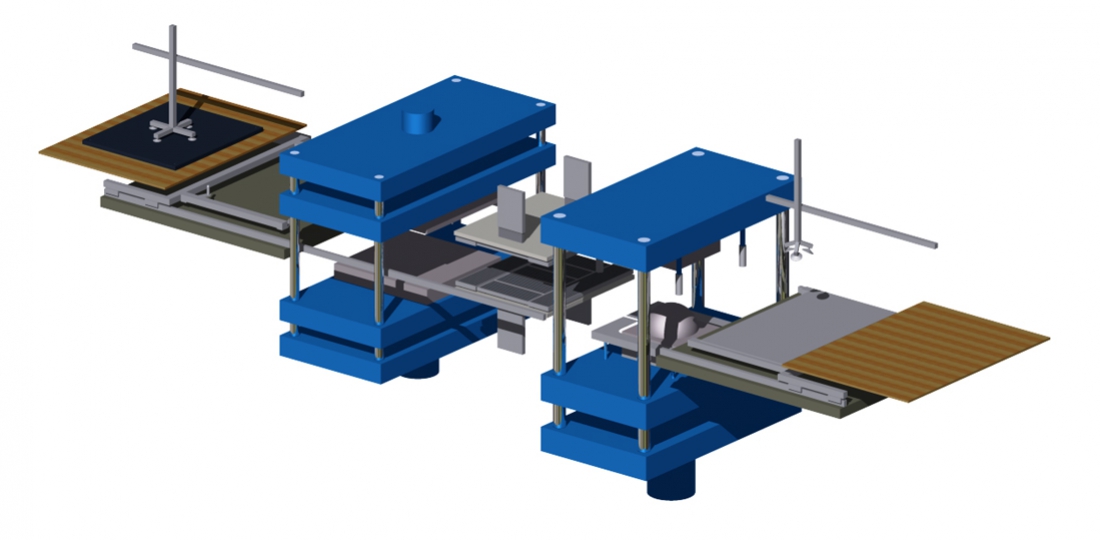

Pre-forming systems

Systems for fully automated manufacturing of drum brake coatings

Press for automated manufacturing of sandwich plates made of blown glass

Press for manufacturing of honeycombed sandwich plates

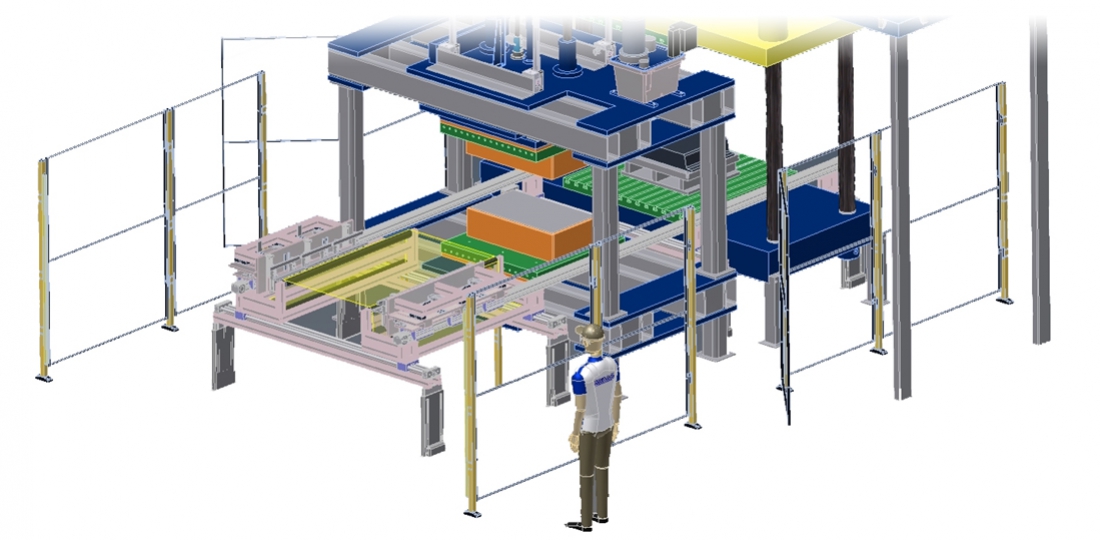

Press for the automated production of

Contact partner

Mr. Andrè Göpfert

Sales

phone +49 (0) 3763 6003 - 19

fax +49 (0) 3763 6003 - 30

send email-message

Mr. Andreas Müller

Sales

phone +49 (0) 3763 6003 - 39

fax +49 (0) 3763 6003 - 30

send email-message